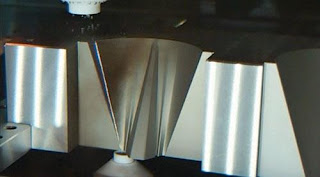

Used wire EDM machines have played an important part in the advancement of the manufacturing department. Primarily, it is a process of metalworking with the aid of which material sets apart from a conductive work piece through electrical erosion. As a result, the wire indeed not very conducive material. The wire electrode will leave a path on the piece, which appears to be larger than the wire.

Implementations Of Used EDM Machines

Used wire EDM machines are primarily used to cut hard patterns and shapes into hard metals, which are hard to mold, manipulate or form. It is advantageous in the aerospace and electronic devices sectors for production and prototyping various parts. In most cases, titanium and steel are highly processed with the assistance wire electrical discharge machining. To trim complex designs like jewelry, this device is used. Also, artists dealing with metals think that machining gear is useful and handy to use. For the most of applications, they are utilized to generate precision parts. Some markets such as medical related, automobile, aerospace, protection, and semiconductor/electric manufacturing will need wire EDM to accomplish firmer tolerances and high precision.

The majority of wire EDM equipment is CNC-controlled. The CNC phrase means "Computer Numerical Control." The objective is to achieve an accurate and precise strategy via a machine, rather than counting on imprecise and incorrect "eyeball" approach. This contemporary wire machine depends solely upon computer systems to guide and chop the wires away. But only the metal is taken out. To cut designs with accuracy and to produce 3D objects, the used EDM machines have proven to be advantageous.

One last benefit of fluid machining through this used machine to lengthen the lifespan of the wire itself. These systems are high maintenance simply because the wires are checked for rating, pitting, damages, and other downfalls frequently. If left abandoned, proof of any of these could lead to the indecent tooling of the item, damage to the device or lack of precision. Through fluid tooling, the wires are retained cool, and the constant rate is utilized in the electrical charges that passed through the wires, thus stretching the life expectancy of the wire.

Each and every machine procedure and electrical discharge machining call for the best EDM supplies. Machining of this kind is used to generate finely detailed parts. They are progressively becoming prominent in the manufacturing sector throughout the world. They are utilized mainly by the production companies in dying of supplies. There are plenty of companies promoting these stuffs, but be sure you obtain the best-used wire EDM machines.

Showing posts with label Used Vertical Turning Lathe. Show all posts

Showing posts with label Used Vertical Turning Lathe. Show all posts

Friday, June 12, 2015

Friday, January 30, 2015

The Role Of Used Mori Seiki in Manufacturing Companies

Used mori seiki takes an extremely important part in the manufacturing production nowadays. It is one of the world’s top producer of CNC machining centers, CNC lathes, and CNC turning centers. The business has formed the current device tool industry. If you check out the vocabulary, the unit is a thing made for a particular objective. It is a contrivance or creation, especially an electric or mechanized one. This pertains to an extensive of used tool such as different kinds of machines and instruments.

More Possibilities: To keep your budget balanced, there’s much money to spend to your warehouse/storage needs are probably not your ultimate priority. As you go through the succeeding path, you may swap minor equipment. When you choose used equipment, you will have the ability to save more money and be capable to purchase more.

Expected Lifespan: Not like the innovative equipment, the “life expectancy” of used equipment is expected. This permits you to estimate fairly the quantity of usage you will have the ability to get out of using the gear.

There are plenty of queries concerning the process of purchasing gear, but the easiest one is most likely the issue that ask with regards to: Should you purchase used or new equipment? While owning a new device may sound beneficial to you, always prioritize your convenience. To help you come up a sensible decision, the benefits have been presented. Bear in mind that is buying used mori seiki outweighs the drawbacks.

Mori Seiki Purposes

- Aerospace - throttle bodies, airline hydraulic cylinder, seat components, and secondary parts of operations.

- Green Energy/Power Generation - Gas fuel body, wind power tool.

- Defense/Military -firearm side handles, gun elements, and molds.

- Railway/Automotive-auto engine fuel pump body, a-arms, suspension parts, suspension, and brake components.

- Medical - molds, cavities, and cores.

- Agriculture- Farm equipment, hydraulic components, tractor hydraulic, farm equipment, and hubs.

Benefits Of Purchasing Used Equipment

It’s less costly: This is probably the greatest advantage of going with used mori seiki. In fact, it’s where the advantages came from. In many instances, going to used equipment won’t help you save much. But other times, the cost variation make it difficult to say no. Almost everything has a price. Nowadays, most things have a higher value. With the high cost of living, purchasing “used” equipment has become progressively popular. Purchasing used equipment can save plenty of cash.More Possibilities: To keep your budget balanced, there’s much money to spend to your warehouse/storage needs are probably not your ultimate priority. As you go through the succeeding path, you may swap minor equipment. When you choose used equipment, you will have the ability to save more money and be capable to purchase more.

Expected Lifespan: Not like the innovative equipment, the “life expectancy” of used equipment is expected. This permits you to estimate fairly the quantity of usage you will have the ability to get out of using the gear.

There are plenty of queries concerning the process of purchasing gear, but the easiest one is most likely the issue that ask with regards to: Should you purchase used or new equipment? While owning a new device may sound beneficial to you, always prioritize your convenience. To help you come up a sensible decision, the benefits have been presented. Bear in mind that is buying used mori seiki outweighs the drawbacks.

Tuesday, January 20, 2015

Used Vertical Turning Lathe: Lathes as Useful Tools for Most Industries

A device which revolves a workpiece on an axis in order to allow for a variety of completely in proportion operations which can include sanding, reducing, drilling or other sort of contortion is known as a lathe. Simply puts the worker will certainly position a things or product into the tool, maybe a brand new or used vertical turning lathe, as well as it will certainly then reverse 360 degrees continuously. By merely holding the carry out in the proper place then, a hobbyist or professional is able to make modification that will certainly affect the whole circumference of the material.

Lathes are utilized in a variety of different industries as well as there are an array of prominent tools related to their usage. The potter's wheel for instance which is extremely preferred is a kind of lathe. It is likewise feasible to ornamental lathes that are designed to be decorative and also collectible. There are also several different types lathe and parts of lathes. Typically the lathe will consist of a pin on which the item will transform, a tool remainder for standing the tool, a tail stock and a lock nob.

The lock nob is used in order to alter and afterwards set the elevation of the tool remainder in order to make sure that the tool that is made use of in order to form the object is held stable and also at the same elevation. Or else you would be likely to find that you ended up drawing strange shaky lines on the things instead of keeping them still therefore developing a straight line. As the object rotates the tool will alter the shape, but because it won't move it won't go into the things despite how many times it is rotated. Hence the line will be totally even all around and also you could then change the position of the tool before making new modifications.

Other portals which lathes vary are that some will turn the object horizontally while others will certainly turn it vertically. On the other hand you will certainly find that some lathes are electrical while older lathes call for a pedal or a deal with in order to cause the challenge revolve. Naturally the rate at which the product revolves is very important too as this effect how well the item cuts depending on the material you are making use of. Lathes additionally vary a lot in size, and also while some are small adequate to be raised and put on a bench or a table, others will certainly be huge as well as will certainly stand openly on workshop floors etc.

The tools that you make use of to apply to the item on the lathe, or a new or utilized vertical turning lather, can additionally vary extensively and these can consist of paintbrushes for painting points that have already set, blades for reducing lines, sanders and declare submitting things down, flamethrowers for collaborating with glass etc and more. In many cases, such as the potters wheel, just hands will certainly be enough to change the form of the clay.

Lathes are utilized in a variety of different industries as well as there are an array of prominent tools related to their usage. The potter's wheel for instance which is extremely preferred is a kind of lathe. It is likewise feasible to ornamental lathes that are designed to be decorative and also collectible. There are also several different types lathe and parts of lathes. Typically the lathe will consist of a pin on which the item will transform, a tool remainder for standing the tool, a tail stock and a lock nob.

The lock nob is used in order to alter and afterwards set the elevation of the tool remainder in order to make sure that the tool that is made use of in order to form the object is held stable and also at the same elevation. Or else you would be likely to find that you ended up drawing strange shaky lines on the things instead of keeping them still therefore developing a straight line. As the object rotates the tool will alter the shape, but because it won't move it won't go into the things despite how many times it is rotated. Hence the line will be totally even all around and also you could then change the position of the tool before making new modifications.

Other portals which lathes vary are that some will turn the object horizontally while others will certainly turn it vertically. On the other hand you will certainly find that some lathes are electrical while older lathes call for a pedal or a deal with in order to cause the challenge revolve. Naturally the rate at which the product revolves is very important too as this effect how well the item cuts depending on the material you are making use of. Lathes additionally vary a lot in size, and also while some are small adequate to be raised and put on a bench or a table, others will certainly be huge as well as will certainly stand openly on workshop floors etc.

The tools that you make use of to apply to the item on the lathe, or a new or utilized vertical turning lather, can additionally vary extensively and these can consist of paintbrushes for painting points that have already set, blades for reducing lines, sanders and declare submitting things down, flamethrowers for collaborating with glass etc and more. In many cases, such as the potters wheel, just hands will certainly be enough to change the form of the clay.

Tuesday, September 9, 2014

Used Vertical Turning Lathe: The Varied Types of Lathe Machines that You Can Use

Lathe tools are used in steel working, wood switching and glass working. A result of the lathe turning, it can establish any kind of product having equilibrium about an axis of turning. Various points made by lathe machine are potters' wheel, music tools, baseball bats, bowls, as well as many more. Thus with this, you could opt to obtain a new or likewise purchase a used vertical turning lathe from any sort of machine-selling stores globally.

Relying on the sort of work required, there are many type of turning lathe devices available to deal with every need. These turning lathe types are mentioned here:

1. Spindle.

Usage of this lathe gadget is found to make sharp products like, table feet.

2. Faceplate.

Using of this lathe device might be seen in the buildup of points like wooden products.

3. Vertical.

This type of lathe is used for faster and also synchronised switching of any kind of part. Vertical turning lathe has structured control terminal along with interlocked electrical control panel providing best control throughout the operation. Any kind of kind of automated reducing as well as increasing of the rails helps in easy packing and unloading of things.

Another type of gizmo is called a flexing machine. In case of tube or pipeline flexing equipments, they can be completed with comfort and precision with the ideal machine. Numerous long lasting benders are used for larger manufacturing houses and also establishments. They can show to be much more budget pleasant as well as beneficial, which could be made use of even without much encounter.

Below are other sorts of benders provided for varied sort of job:

1. Press benders.

Mechanical drive generates the flex by pressing any tube versus a die in this bender. It is discovered to be one fundamental sort of bender. And, in this bender, force is utilized pneumatically or hydraulically and also it relies on the setup of the machine.

2. Roll benders.

Roll benders are rather various from numerous other sort of benders, as they progressively change the flex span in the pipe over numerous relocate to the rollers.

3. Rotating benders.

This type of rotating draw bender is more ironed out in its bends, because of the fact that it deals with a continual center radius.

Bear in mind, when acquiring heavy operated devices like a used vertical turning lathe or a roll bender, see to it that you inspect the producer's or vendor's credibility. View if they have consumer assessments readily available in their website or view if you could track their marketing records. No person would intend to get a substandard machines for certain.

Relying on the sort of work required, there are many type of turning lathe devices available to deal with every need. These turning lathe types are mentioned here:

1. Spindle.

Usage of this lathe gadget is found to make sharp products like, table feet.

2. Faceplate.

Using of this lathe device might be seen in the buildup of points like wooden products.

3. Vertical.

This type of lathe is used for faster and also synchronised switching of any kind of part. Vertical turning lathe has structured control terminal along with interlocked electrical control panel providing best control throughout the operation. Any kind of kind of automated reducing as well as increasing of the rails helps in easy packing and unloading of things.

Another type of gizmo is called a flexing machine. In case of tube or pipeline flexing equipments, they can be completed with comfort and precision with the ideal machine. Numerous long lasting benders are used for larger manufacturing houses and also establishments. They can show to be much more budget pleasant as well as beneficial, which could be made use of even without much encounter.

Below are other sorts of benders provided for varied sort of job:

1. Press benders.

Mechanical drive generates the flex by pressing any tube versus a die in this bender. It is discovered to be one fundamental sort of bender. And, in this bender, force is utilized pneumatically or hydraulically and also it relies on the setup of the machine.

2. Roll benders.

Roll benders are rather various from numerous other sort of benders, as they progressively change the flex span in the pipe over numerous relocate to the rollers.

3. Rotating benders.

This type of rotating draw bender is more ironed out in its bends, because of the fact that it deals with a continual center radius.

Bear in mind, when acquiring heavy operated devices like a used vertical turning lathe or a roll bender, see to it that you inspect the producer's or vendor's credibility. View if they have consumer assessments readily available in their website or view if you could track their marketing records. No person would intend to get a substandard machines for certain.

Monday, June 2, 2014

Using Secondhand Machine Tools Effectively Like a Used Vertical Turning Lathe

Machine devices are known as as tools that are vital in doing away with operations for item removal. It operates various running principles like grinding, developing, turning, burrowing and milling. Machine tools are relatively expensive and not all could possibly have the capacity to obtain new devices for a particular feature. It is in this hookup that secondhand machine units, similar to a used vertical turning lathe are readily available in the market.

The real functions of these items are diverse. Originally, they plan to supply uniformity in between the movement of the work piece and the cutting instrument made use of. It also has to make tightness while the slicing procedure is executed. In addition, it supplies consistency throughout the reducing treatment while it takes care of vibrations at the same time. Add to that, it similarly helps help in exact surface area finishes. With these attributes, one might have the ability to look at how reliable second-hand machine devices are.

Machine Devices Style and design

Understanding what equipment are made from will certainly help one find out methods to buy secondhand devices for production. An optimal tool is created from metal and heavy iron. Forged iron is normally seen at its bottom degree while the entire framework is normally put on concrete flooring. Running the device is assisted in with the use of screws, axles and tools. If possible, machine devices are stated to be effective if and when their particular cutting devices move conveniently.

Techniques of Machinery

In the process, the turning or task is backed up by the movements of 3 spatial centers. Screws, shelf and pinion plans, linear tips and bearings are essential in the procedure.

Machine tool devices consist of a platform and a structure. These components are utilized either of 2 techniques:.

a) the gadget is clutched by the tower while the work item or product is connected on the base; or.

b) the instrument is bound under level while the work piece or product is put on the tower.

Various kind of devices

When trying to find machine categories, various classifications could emerge. The various classifications are also sub-categorized into specific kinds. When looking for pre-owned machine devices such as a used vertical turning lathe, classifications like air cooling and filtering system devices, bar machines, bending and developing devices, boring mills and air compressors could be discovered. Different various other machine tools to search for are drilling equipments, broaching devices, die casting devices and EDM products. Furthermore, questions for manufacturing devices, electric and energy devices, saws, fasteners and building equipments could furthermore be produced. Along these numerous kinds, there are various products an individual could pick from. This will now hinge on the demands of the business or the person.

The real functions of these items are diverse. Originally, they plan to supply uniformity in between the movement of the work piece and the cutting instrument made use of. It also has to make tightness while the slicing procedure is executed. In addition, it supplies consistency throughout the reducing treatment while it takes care of vibrations at the same time. Add to that, it similarly helps help in exact surface area finishes. With these attributes, one might have the ability to look at how reliable second-hand machine devices are.

Machine Devices Style and design

Understanding what equipment are made from will certainly help one find out methods to buy secondhand devices for production. An optimal tool is created from metal and heavy iron. Forged iron is normally seen at its bottom degree while the entire framework is normally put on concrete flooring. Running the device is assisted in with the use of screws, axles and tools. If possible, machine devices are stated to be effective if and when their particular cutting devices move conveniently.

Techniques of Machinery

In the process, the turning or task is backed up by the movements of 3 spatial centers. Screws, shelf and pinion plans, linear tips and bearings are essential in the procedure.

Machine tool devices consist of a platform and a structure. These components are utilized either of 2 techniques:.

a) the gadget is clutched by the tower while the work item or product is connected on the base; or.

b) the instrument is bound under level while the work piece or product is put on the tower.

Various kind of devices

When trying to find machine categories, various classifications could emerge. The various classifications are also sub-categorized into specific kinds. When looking for pre-owned machine devices such as a used vertical turning lathe, classifications like air cooling and filtering system devices, bar machines, bending and developing devices, boring mills and air compressors could be discovered. Different various other machine tools to search for are drilling equipments, broaching devices, die casting devices and EDM products. Furthermore, questions for manufacturing devices, electric and energy devices, saws, fasteners and building equipments could furthermore be produced. Along these numerous kinds, there are various products an individual could pick from. This will now hinge on the demands of the business or the person.

Friday, March 21, 2014

Used Mori Seiki: Machinability And The Importance Of Using Machining Centres

Machinability is a common phrase which refers to how easily a product can be machined in machining centres, either new or old instruments such as a used Mori Seiki equipment. The technique of machining something consists of eliminating pieces of it with a series of various machine devices like power saws on a production line in a factory. Materials are machined to be able to position them into a particular design.

Various elements enter into quantifying machinability. For instance, a product could be easy to cut, however might be difficult on the devices used to cut it. This would produce bad quality since it's not worthwhile to use a material over the long term if it continually bends or chips the power equipment utilized while doing so. Even products that can be broken down easily in machining centres might not make for great machinability. A good example is thermoplastics, since they have the tendency to melt and afterwards stream round the blades of saws rather than being cut and then easily eliminated.

Computing machinability is a typically tough procedure and it's typically concentrated on one certain process in machining centres. The foremost and a lot of apparent means to measure this is the "tool life method." This approach concentrates directly on how long machine equipment last when they work with the material. This approach is best when it's essential to compare the probability or quality of one compound against another element of very similar quality. It's useful to know which product will harm the devices of machining centres. The downside is that this technique might give incorrect readings if the testers don't thoroughly account for various other factors that might increase ruin, like the geometry of the cutting instrument, the speed of the devices, and many others.

Tool forces and power use is another means to evaluate a compound's machinability. The quantity of energy it costs to puncture a product with machining instruments will provide an excellent concept for how appropriate the compound is for machining generally. This provides a quantifiable amount that will let machinists examine substances versus each other.

The surface finish technique for machinability measures how much of a troublesome edge products develop during the machining process. This side makes it more difficult to machine the product. Stainless steel is one good example of a material that has the tendency to develop built-up edges in machining centres like a new or used Mori Seiki machining center, therefore is not fit for the machining procedure. This will make materials like aluminum alloys and cold worked steels, that do not have the tendency to get that end, better for use with machine equipment.

Various elements enter into quantifying machinability. For instance, a product could be easy to cut, however might be difficult on the devices used to cut it. This would produce bad quality since it's not worthwhile to use a material over the long term if it continually bends or chips the power equipment utilized while doing so. Even products that can be broken down easily in machining centres might not make for great machinability. A good example is thermoplastics, since they have the tendency to melt and afterwards stream round the blades of saws rather than being cut and then easily eliminated.

Computing machinability is a typically tough procedure and it's typically concentrated on one certain process in machining centres. The foremost and a lot of apparent means to measure this is the "tool life method." This approach concentrates directly on how long machine equipment last when they work with the material. This approach is best when it's essential to compare the probability or quality of one compound against another element of very similar quality. It's useful to know which product will harm the devices of machining centres. The downside is that this technique might give incorrect readings if the testers don't thoroughly account for various other factors that might increase ruin, like the geometry of the cutting instrument, the speed of the devices, and many others.

Tool forces and power use is another means to evaluate a compound's machinability. The quantity of energy it costs to puncture a product with machining instruments will provide an excellent concept for how appropriate the compound is for machining generally. This provides a quantifiable amount that will let machinists examine substances versus each other.

The surface finish technique for machinability measures how much of a troublesome edge products develop during the machining process. This side makes it more difficult to machine the product. Stainless steel is one good example of a material that has the tendency to develop built-up edges in machining centres like a new or used Mori Seiki machining center, therefore is not fit for the machining procedure. This will make materials like aluminum alloys and cold worked steels, that do not have the tendency to get that end, better for use with machine equipment.

Friday, March 14, 2014

Vertical Machining Center: Understanding the Works of Precision Tools

Precision machining tools, such as a vertical machining center, have already been significantly improved by linear encoders in a variety of means. A linear encoder is a sensor, transducer or readhead coupleded with a scale that encodes position. It operates by the sensor reviewing the scale and converting that encoded position into a digital signal which is then decoded in place by an electronic readout. Linear encoders are gentlied used in metrology instruments and precision machining instruments such as digital calipers and coordinate measuring equipments. Linear encoders gently used lots of different physical qualities to scribe the location just like magnetic, capacitive, optical and magnetic.

Optical linear encoders are the most widely used type of encoder on the market today especially for precision machining instruments. A common scale for optical linear encoders differs from hundreds of microns down to simply a few. This kind of scale is very accurate and precise which is why it dominates the majority of the marketplace. The magnetic encoders are an additional preferred and they work by scales that are either dynamic which is allured or inactive which is unwillingness.

There are two major applications for linear encoders consisting of measurement and motion systems. Measurement is specifically crucial when it pertains to accuracy machining since it should be accurate down to the hundredth of a millimeter. Linear encoders for measurement are typically found in coordinate measuring machines (CMM), laser scanners, calipers, equipment measurement, stress testers, and digital read outs. Motion systems from linear encoder also aid accuracy machining because they supply precise high speed motion. Linear encoders are either open or closed which can bring various benefits and drawbacks. Being open they are prone to dirt specifically being in precision machining tools and machines. However confining the encoder restricts it accuracy due to rubbing. The choice of the encoder being shut or open in a machine needs to be considered on a case by case basis.

Cold Forging and Precision Machining

It's been found and tested that accuracy cold forging creates perfectly shaped parts with basic or complicated geometry and it's quicker than machining. Accuracy machining is the most popular method of producing tools and parts for machinery however it is very pricey due to the machines and the duration it takes to produce the parts. Forging can work on cold or hot products; cold working is conducted at certain temperatures, and hot working at across the recrystallisation temperature of the product being forged.

Typically applying arduous and heavy deformation to cold steel cracks the steel but by keeping pressure at all points this does not occur. By utilizing small elements cold forging can create a final shape with stainless steel providing they are well lubed and included. Cold forging makes products specifically to their shape which can not be attained with hot creating, and since with cold creating parts can typically be formed in one blow manufacturing rates are really high. Cold creating is a great alternative to accuracy machining due to the fact that it cuts the machining time quite significantly which for a company means decreases expenses on producing parts and a much faster rate at which they can be provided.

Machining tools are known to be extremely crucial in the manufacturing industry. Hence, finding a dependable machine tool like a vertical machining center, is important to be able to do all the essential tasks needed in business manufacturing.

Optical linear encoders are the most widely used type of encoder on the market today especially for precision machining instruments. A common scale for optical linear encoders differs from hundreds of microns down to simply a few. This kind of scale is very accurate and precise which is why it dominates the majority of the marketplace. The magnetic encoders are an additional preferred and they work by scales that are either dynamic which is allured or inactive which is unwillingness.

There are two major applications for linear encoders consisting of measurement and motion systems. Measurement is specifically crucial when it pertains to accuracy machining since it should be accurate down to the hundredth of a millimeter. Linear encoders for measurement are typically found in coordinate measuring machines (CMM), laser scanners, calipers, equipment measurement, stress testers, and digital read outs. Motion systems from linear encoder also aid accuracy machining because they supply precise high speed motion. Linear encoders are either open or closed which can bring various benefits and drawbacks. Being open they are prone to dirt specifically being in precision machining tools and machines. However confining the encoder restricts it accuracy due to rubbing. The choice of the encoder being shut or open in a machine needs to be considered on a case by case basis.

Cold Forging and Precision Machining

It's been found and tested that accuracy cold forging creates perfectly shaped parts with basic or complicated geometry and it's quicker than machining. Accuracy machining is the most popular method of producing tools and parts for machinery however it is very pricey due to the machines and the duration it takes to produce the parts. Forging can work on cold or hot products; cold working is conducted at certain temperatures, and hot working at across the recrystallisation temperature of the product being forged.

Typically applying arduous and heavy deformation to cold steel cracks the steel but by keeping pressure at all points this does not occur. By utilizing small elements cold forging can create a final shape with stainless steel providing they are well lubed and included. Cold forging makes products specifically to their shape which can not be attained with hot creating, and since with cold creating parts can typically be formed in one blow manufacturing rates are really high. Cold creating is a great alternative to accuracy machining due to the fact that it cuts the machining time quite significantly which for a company means decreases expenses on producing parts and a much faster rate at which they can be provided.

Machining tools are known to be extremely crucial in the manufacturing industry. Hence, finding a dependable machine tool like a vertical machining center, is important to be able to do all the essential tasks needed in business manufacturing.

Thursday, March 13, 2014

Used Vertical Machining Center: The Progress of Machine Tools Through the Years

The industrial innovation grew mostly in the later years. The expansion of the machine tool as a vital tool started from this time. A machine tool is a gadget that works on power and is utilized to devise metal parts of machines. The tool produces specific machine parts by eliminating metal on a selective groundwork. A machine tool typically creates in the mind, an image of a tool that runs through the help of external power and no tool that is run by human beings. Nevertheless, a machine instrument can, in particular cases, be run by human beings too. And these machines can anytime be made use of new or secondhand, just similar to a used vertical machining center.

How Machine Tools Work

A machine device might be operated in many methods. A crude tool is generally mechanically powered by human beings or animals. Because the late nineteenth and the very early twentieth century, a large area of machine parts and tools have been operating on electrical power. The very first machine parts and tools utilized flywheels in order to run properly and were also supported by an entire range of gears and levers. Before, there was an unexpected wave of numerical control machines or NC equipments in production industries. Later, there has been a foray of computer technology into the machine tool manufacturing industry and the progression of the very first computerized numerical control equipments or what we call now as CNC machines. Both CNC and NC machines had the capability to produce high-end tools and pieces, something that even skilled tool makers might not do.

Computer Machine Engineering

Little by little, with the stable development of computer system and electronic innovation, equipments that could instantly modify hacking and molding tools, came into being. Sophisticated machine tools were established that assisted in the development of equipments that sped up assembly-line and production procedures by a substantial degree. A machine instrument is a tool that has the ability to make copies of itself and construct machine parts. As the tool making knowledge started to be an increasing number of integrated with technological knowhow, countless machine parts and tools were made that could be controlled with the help of computer systems. By the 1980's, computer systems became a dominant and the most crucial element of the tool-making business and drastically metamorphosed the way a machine tool was built.

Modern day Machine Resources called Software Tools

At present, in the period of computer systems and electronic devices, a lot of complicated machine parts and tools are crafted making use of advanced computer and electronic innovation. Such innovation assists in the creation of machine instruments on a large scale assisting makers exploit the advantages of the economies of scale. Computer technology is so clever that it helps in the creation of tailored tools specifically according to specifications. What's more, computer innovation has likewise caused a major change in the nature and qualities of the machine instrument that it assists to develop. While the standard tool was something concrete, that could be felt, that had particular measurements, the modern machine part or tool is no more a tangible things however an intangible software, much better called a software tool. It is to this classification of tools that the online diary planner belongs.

With this time period, it is not impossible anymore to effectively develop machine parts making use of computer technology. This contributes to an enhanced manufacturing level in the equipment market and at the same time, increases efficiency level of workers. It does not matter whether you use new tools or secondhand ones, like a used vertical machining center. What matters most is that you are making use of a safe and effective device which may help you maximize your production level.

How Machine Tools Work

A machine device might be operated in many methods. A crude tool is generally mechanically powered by human beings or animals. Because the late nineteenth and the very early twentieth century, a large area of machine parts and tools have been operating on electrical power. The very first machine parts and tools utilized flywheels in order to run properly and were also supported by an entire range of gears and levers. Before, there was an unexpected wave of numerical control machines or NC equipments in production industries. Later, there has been a foray of computer technology into the machine tool manufacturing industry and the progression of the very first computerized numerical control equipments or what we call now as CNC machines. Both CNC and NC machines had the capability to produce high-end tools and pieces, something that even skilled tool makers might not do.

Computer Machine Engineering

Little by little, with the stable development of computer system and electronic innovation, equipments that could instantly modify hacking and molding tools, came into being. Sophisticated machine tools were established that assisted in the development of equipments that sped up assembly-line and production procedures by a substantial degree. A machine instrument is a tool that has the ability to make copies of itself and construct machine parts. As the tool making knowledge started to be an increasing number of integrated with technological knowhow, countless machine parts and tools were made that could be controlled with the help of computer systems. By the 1980's, computer systems became a dominant and the most crucial element of the tool-making business and drastically metamorphosed the way a machine tool was built.

Modern day Machine Resources called Software Tools

At present, in the period of computer systems and electronic devices, a lot of complicated machine parts and tools are crafted making use of advanced computer and electronic innovation. Such innovation assists in the creation of machine instruments on a large scale assisting makers exploit the advantages of the economies of scale. Computer technology is so clever that it helps in the creation of tailored tools specifically according to specifications. What's more, computer innovation has likewise caused a major change in the nature and qualities of the machine instrument that it assists to develop. While the standard tool was something concrete, that could be felt, that had particular measurements, the modern machine part or tool is no more a tangible things however an intangible software, much better called a software tool. It is to this classification of tools that the online diary planner belongs.

With this time period, it is not impossible anymore to effectively develop machine parts making use of computer technology. This contributes to an enhanced manufacturing level in the equipment market and at the same time, increases efficiency level of workers. It does not matter whether you use new tools or secondhand ones, like a used vertical machining center. What matters most is that you are making use of a safe and effective device which may help you maximize your production level.

Wednesday, March 12, 2014

Know How CNC Machines Like a Samsung Lathe Centre Work in Easing Out the Overall Business Manufacturing Process

The development and proliferation of electric motors in the very early times inevitably led to conventional kinds of lathes becoming electrically powered. This was the first major step towards today's computer managed lathes, and happened as manufacturers sought to increase productivity and lower expenses. A Computer Numerical Controller describes a computer that reviews machine code guidelines so as to control a machine tool. Computer Numerically Controlled or CNC machine tools are usually utilized for machining basic material stocks into completed designs by carrying out a series of such instructions. CNC lathes, such as a Samsung lathe center, are likely the most commonly acknowledged usage of this engineering technology. They rotate a block of material so it can be cut, sanded, drilled or finished, with the end outcome being a completed three-dimensional product. In reality, CNC lathes are simply the like an old-fashioned turret lathe, however running under computer control.

Important Elements

Modern CNC lathes are a mix of a computer with a lathe machine and a controller that transforms each digital sign into the preferred action. Specialized software program is first used to create the necessary style that needs to be duplicated physically on metal, wood, etc. The work piece is next installed on the chuck and rotated at slow or high rates of speed depending upon the product and the kind of cut or focusing needed. The computer system then manages the cutting action of the lathe as required to be able to produce the finished product. Modern day lathes can have multiple spindles so that several changes can be accomplished on the end item without having to halt and stock up it in a various positioning.

CNC lathes are usually equipped with 3 jaw hydraulic chucks. Holding of the raw material to be transformed is generally finished with hard jaws or bored soft jaws. Lathes might also have a collet chuck. This enables adjustable size and accurate holding minus the demand for soft jaw boring. When gearing up a lathe with a collet chuck, it may be necessary to modify or alter the draw bar linking the actuator to the chuck. The tool bits that are needed to puncture steel are typically made from tungsten carbide, titanium carbide, and various other tough alloys depending upon the product that should be cut. The tool little bits are made use of till the limit extremes are maintained after which they are either honed where possible, or replaced with a new bit.

In spite of their accuracy, CNC lathes usually need an excellent operator to oversee the mechanized process. This is still an extremely quicker, more fruitful and more cost efficient choice than traditional lathes could achieve. A developer is also required to compile the program directions had to instruct the equipment in the first place.

Activitying a CNC lathe like a Samsung lathe center first of all needs a plan of the item to be produced. After the plan is analyzed, the shows of the cutting tools required for making each part can then be begun. Every move in 3 measurements is set, in incredibly great information. A lot of skill and quality testimonial is needed at this stage to ensure no problems take place when the system is running in the live surroundings.

Important Elements

Modern CNC lathes are a mix of a computer with a lathe machine and a controller that transforms each digital sign into the preferred action. Specialized software program is first used to create the necessary style that needs to be duplicated physically on metal, wood, etc. The work piece is next installed on the chuck and rotated at slow or high rates of speed depending upon the product and the kind of cut or focusing needed. The computer system then manages the cutting action of the lathe as required to be able to produce the finished product. Modern day lathes can have multiple spindles so that several changes can be accomplished on the end item without having to halt and stock up it in a various positioning.

CNC lathes are usually equipped with 3 jaw hydraulic chucks. Holding of the raw material to be transformed is generally finished with hard jaws or bored soft jaws. Lathes might also have a collet chuck. This enables adjustable size and accurate holding minus the demand for soft jaw boring. When gearing up a lathe with a collet chuck, it may be necessary to modify or alter the draw bar linking the actuator to the chuck. The tool bits that are needed to puncture steel are typically made from tungsten carbide, titanium carbide, and various other tough alloys depending upon the product that should be cut. The tool little bits are made use of till the limit extremes are maintained after which they are either honed where possible, or replaced with a new bit.

In spite of their accuracy, CNC lathes usually need an excellent operator to oversee the mechanized process. This is still an extremely quicker, more fruitful and more cost efficient choice than traditional lathes could achieve. A developer is also required to compile the program directions had to instruct the equipment in the first place.

Activitying a CNC lathe like a Samsung lathe center first of all needs a plan of the item to be produced. After the plan is analyzed, the shows of the cutting tools required for making each part can then be begun. Every move in 3 measurements is set, in incredibly great information. A lot of skill and quality testimonial is needed at this stage to ensure no problems take place when the system is running in the live surroundings.

On Utilizing Used Machine Tools Like a Used Vertical Turning Lathe

Machine tools are called devices that are vital in getting rid of operations for product removal. It operates various operating concepts like grinding, shaping, turning, burrowing and milling. Machine tools are fairly pricey and not all might have the ability to buy brand new equipment for a particular function. It is in this regard that used machine tools, like a used vertical turning lathe are available in the marketplace.

The real functions of such items are differed. Initially, they intend to offer steadiness in between the motion of the work piece and the slicing tool used. It likewise needs to render tightness while the chopping procedure is done. Moreover, it supplies consistency throughout the cutting treatment while it regulates vibrations while doing so. Contribute to that, it likewise helps facilitate accurate surface area finishes. With these capabilities, one might have the ability to explore how efficient pre-owned machine tools are.

Procedures of Machinery

Machine tool equipment are comprised of a base and a structure. These elements are utilized either of two means:

a) the product is fixed on the bottom level while the work piece or material is put on the tower; or.

b) the machine is held by the tower while the work piece or material is fixed on the base.

In the operation, the spinning or activity is supported by the motions of 3 spatial axes. Screws, rack and pinion plans, linear guides and bearings are essential in the procedure.

Machine Devices Design

Knowing what instruments are made of will help one discover how to buy pre-owned machines for production. An ideal tool is fabricated from steel and heavy iron. Cast iron is typically seen at its base while the whole framework is generally fixed on concrete. Powering the equipment is made easy with the usage of screws, axles and gears. Ideally, machine devices are said to be effective if and when their particular cutting tools move easily.

Various types of equipment

When searching for machine groups, various classifications may arise. The different categories are likewise sub-categorized into certain types. When trying to find used machine equipment such as a used vertical turning lathe, categories like air cooling and filtering equipment, bar machinery, bending and forming devices, boring mills and air compressors might be found. Various other machine tools to try to find are drilling devices, broaching machines, die casting devices and EDM machines. Additionally, inquiries for fabrication devices, electrical and power devices, saws, fasteners and forging equipments may also be made. Along these various types, there are different products an individual might pick from. This will now depend on the requirements of the company or the individual.

The real functions of such items are differed. Initially, they intend to offer steadiness in between the motion of the work piece and the slicing tool used. It likewise needs to render tightness while the chopping procedure is done. Moreover, it supplies consistency throughout the cutting treatment while it regulates vibrations while doing so. Contribute to that, it likewise helps facilitate accurate surface area finishes. With these capabilities, one might have the ability to explore how efficient pre-owned machine tools are.

Procedures of Machinery

Machine tool equipment are comprised of a base and a structure. These elements are utilized either of two means:

a) the product is fixed on the bottom level while the work piece or material is put on the tower; or.

b) the machine is held by the tower while the work piece or material is fixed on the base.

In the operation, the spinning or activity is supported by the motions of 3 spatial axes. Screws, rack and pinion plans, linear guides and bearings are essential in the procedure.

Machine Devices Design

Knowing what instruments are made of will help one discover how to buy pre-owned machines for production. An ideal tool is fabricated from steel and heavy iron. Cast iron is typically seen at its base while the whole framework is generally fixed on concrete. Powering the equipment is made easy with the usage of screws, axles and gears. Ideally, machine devices are said to be effective if and when their particular cutting tools move easily.

Various types of equipment

When searching for machine groups, various classifications may arise. The different categories are likewise sub-categorized into certain types. When trying to find used machine equipment such as a used vertical turning lathe, categories like air cooling and filtering equipment, bar machinery, bending and forming devices, boring mills and air compressors might be found. Various other machine tools to try to find are drilling devices, broaching machines, die casting devices and EDM machines. Additionally, inquiries for fabrication devices, electrical and power devices, saws, fasteners and forging equipments may also be made. Along these various types, there are different products an individual might pick from. This will now depend on the requirements of the company or the individual.

Monday, November 18, 2013

Used Vertical Turning Lathe: Increasing Production with the Help of the Right Tool

Lathe turning is a procedure where any raw material is cut, deformed and knurled into other object. Lathe machines are used in metal working, wood turning and glass working. Because of the lathe turning, it can produce any object having proportion about an axis of rotation. Use of turning lathe can be seen in pottery work. Among the most popular things made by lathe turning is potter's wheel. Various things produced by lathe equipment are table legs, candlestick cases, instruments for music, baseball bats, containers and many others. And you can likewise purchase used vertical turning lathe from any machine-selling stores around the world.

Based on the necessity of labor, there are various kinds of lathe machines to choose from:

a. Vertical turning Lathe

This kind of lathe is used for faster and synchronised turning of any element. Vertical turning lathe has centralized control station in addition to interlocked electrical control board offering best control throughout the operation. Any kind of automatic lowering and raising of the rails assists in easy filling and unloading of the things. Often times, vertical turning lathe comes with added attachments for milling and grinding.

b. Faceplate turning lathe

Utilization of this lathe device can be seen in the creation of things like, wooden objects.

c. Spindle turning lathe

Using of this lathe device is found to form pointed things like, table legs. Beginning with the procedure of changing the piece of wood into any completed things, any raw material is fixed from both the sides.

One more type of gadget is known as a bending machine. In case of tube or pipe bending equipments, they can be finished with convenience and accuracy with the right machine. Different heavy-duty benders are made use of for larger manufacturing residences and factory. They can show to be more cost effective and practical, which can be made use of even without much experience. There are different kinds of benders readily available for different sort of work:.

a. Rotary benders

This kind of rotary draw bender is a lot more arranged out in its bends, due to the fact that it deals with a consistent center radius.

b. Roll benders

Roll benders are quite different from other kinds of benders, as they progressively change the flex radius in the pipe over several passes to the rollers.

c. Press benders

Mechanical pressure creates the bend by pressing any tube against a die in this bender. It is found to be one fundamental sort of bender. And, in this bender, power is applied pneumatically or hydraulically and it relies on the configuration of the machine.

Bear in mind, when purchasing heavy-powered tools such as a used vertical turning lathe or a roll bender, make sure that you inspect the manufacturer's or seller's track record. See whether they have consumer evaluations offered in their webpage or see whether you can track their selling records. Certainly, you don't wish to end up buying an inept device, correct?

Based on the necessity of labor, there are various kinds of lathe machines to choose from:

a. Vertical turning Lathe

This kind of lathe is used for faster and synchronised turning of any element. Vertical turning lathe has centralized control station in addition to interlocked electrical control board offering best control throughout the operation. Any kind of automatic lowering and raising of the rails assists in easy filling and unloading of the things. Often times, vertical turning lathe comes with added attachments for milling and grinding.

b. Faceplate turning lathe

Utilization of this lathe device can be seen in the creation of things like, wooden objects.

c. Spindle turning lathe

Using of this lathe device is found to form pointed things like, table legs. Beginning with the procedure of changing the piece of wood into any completed things, any raw material is fixed from both the sides.

One more type of gadget is known as a bending machine. In case of tube or pipe bending equipments, they can be finished with convenience and accuracy with the right machine. Different heavy-duty benders are made use of for larger manufacturing residences and factory. They can show to be more cost effective and practical, which can be made use of even without much experience. There are different kinds of benders readily available for different sort of work:.

a. Rotary benders

This kind of rotary draw bender is a lot more arranged out in its bends, due to the fact that it deals with a consistent center radius.

b. Roll benders

Roll benders are quite different from other kinds of benders, as they progressively change the flex radius in the pipe over several passes to the rollers.

c. Press benders

Mechanical pressure creates the bend by pressing any tube against a die in this bender. It is found to be one fundamental sort of bender. And, in this bender, power is applied pneumatically or hydraulically and it relies on the configuration of the machine.

Bear in mind, when purchasing heavy-powered tools such as a used vertical turning lathe or a roll bender, make sure that you inspect the manufacturer's or seller's track record. See whether they have consumer evaluations offered in their webpage or see whether you can track their selling records. Certainly, you don't wish to end up buying an inept device, correct?

Subscribe to:

Posts (Atom)