Used wire EDM machines have played an important part in the advancement of the manufacturing department. Primarily, it is a process of metalworking with the aid of which material sets apart from a conductive work piece through electrical erosion. As a result, the wire indeed not very conducive material. The wire electrode will leave a path on the piece, which appears to be larger than the wire.

Implementations Of Used EDM Machines

Used wire EDM machines are primarily used to cut hard patterns and shapes into hard metals, which are hard to mold, manipulate or form. It is advantageous in the aerospace and electronic devices sectors for production and prototyping various parts. In most cases, titanium and steel are highly processed with the assistance wire electrical discharge machining. To trim complex designs like jewelry, this device is used. Also, artists dealing with metals think that machining gear is useful and handy to use. For the most of applications, they are utilized to generate precision parts. Some markets such as medical related, automobile, aerospace, protection, and semiconductor/electric manufacturing will need wire EDM to accomplish firmer tolerances and high precision.

The majority of wire EDM equipment is CNC-controlled. The CNC phrase means "Computer Numerical Control." The objective is to achieve an accurate and precise strategy via a machine, rather than counting on imprecise and incorrect "eyeball" approach. This contemporary wire machine depends solely upon computer systems to guide and chop the wires away. But only the metal is taken out. To cut designs with accuracy and to produce 3D objects, the used EDM machines have proven to be advantageous.

One last benefit of fluid machining through this used machine to lengthen the lifespan of the wire itself. These systems are high maintenance simply because the wires are checked for rating, pitting, damages, and other downfalls frequently. If left abandoned, proof of any of these could lead to the indecent tooling of the item, damage to the device or lack of precision. Through fluid tooling, the wires are retained cool, and the constant rate is utilized in the electrical charges that passed through the wires, thus stretching the life expectancy of the wire.

Each and every machine procedure and electrical discharge machining call for the best EDM supplies. Machining of this kind is used to generate finely detailed parts. They are progressively becoming prominent in the manufacturing sector throughout the world. They are utilized mainly by the production companies in dying of supplies. There are plenty of companies promoting these stuffs, but be sure you obtain the best-used wire EDM machines.

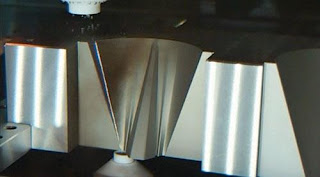

Vertical Machining Center

Friday, June 12, 2015

Tuesday, March 24, 2015

Used Mori Seiki: The Best Time To Purchase A New Tool

Betting on the general performance of new equipments against utilized ones is an inevitable conclusion. In woodworking, there are some circumstances when buying the latter is a lot more sensible compared to getting the former, specifically when it showcases industrial quality design. Unlike pastime grade as well as mid quality machines, commercial quality machinery could last for decades, providing leading efficiency regardless of regular usage under hash conditions, such as those found in high capability woodworking manufacturing plants like a used mori seiki.

If you are thinking about getting commercial woodworking equipment used instead of new, here are four situations in which acquiring it pre-owned makes the most sense.

1. You need more than one machine within a short duration

For some woodworkers, upping production means buying 2 or even more equipments within a brief timeframe. If this explains your scenario, spending the majority of your cash in one machine and then identifying methods to get the others does not make much sense, and also might result in undesirable financing.

Some woodworkers do this when they buy CNC machines. As opposed to very carefully examining a secondhand machine, they buy a new one to guarantee that its computer and cutter heads run as expected. Secondhand CNC equipment could supply the same performance as new devices.

2. You are investing in a bigger workspace

If you are relocating to a new facility whose acquisition will use up most of your cost budget, upgrading your tools with pre-owned devices can be the very best step. While everyone desires new devices when beginning a new endeavor, purchasing them previously owned will certainly make the transition much more economical and also allow you recognize much more profits as revenue.

3. You require machines to satisfy raised production need

The majority of woodworkers desire high manufacturing demand. When that demand becomes frustrating, woodworkers usually discover themselves in the position of requiring one or more new equipments nearly immediately.

The problem, obviously, is that revenue from enhanced manufacturing demand justifies the machinery purchase, however it can not be recognized without the equipment. In such covers, buying equipment used instead of financing new devices is the reasonable choice. When your income overtakes your production rate, you can get new equipment as you kindly.

4. You are beginning an official woodworking business

If you are going from being a casual woodworker to one who gains a source of income from his or her skills with timber, lessening business financing should be a main objective. The much less you owe, the a lot more earnings you could realize as income as well as placed toward developing your assembly line.

Acquiring made use of industrial equipment could need financing as well, however bear in mind, the less you financing, the much more you earn. For small businesses, this basic relationship could suggest the difference between success as well as failure. Buying professional woodworking equipment is a serious choice, however purchasing it pre-owned, like a used mori seiki, can make the decision easier.

If you are thinking about getting commercial woodworking equipment used instead of new, here are four situations in which acquiring it pre-owned makes the most sense.

1. You need more than one machine within a short duration

For some woodworkers, upping production means buying 2 or even more equipments within a brief timeframe. If this explains your scenario, spending the majority of your cash in one machine and then identifying methods to get the others does not make much sense, and also might result in undesirable financing.

Some woodworkers do this when they buy CNC machines. As opposed to very carefully examining a secondhand machine, they buy a new one to guarantee that its computer and cutter heads run as expected. Secondhand CNC equipment could supply the same performance as new devices.

2. You are investing in a bigger workspace

If you are relocating to a new facility whose acquisition will use up most of your cost budget, upgrading your tools with pre-owned devices can be the very best step. While everyone desires new devices when beginning a new endeavor, purchasing them previously owned will certainly make the transition much more economical and also allow you recognize much more profits as revenue.

3. You require machines to satisfy raised production need

The majority of woodworkers desire high manufacturing demand. When that demand becomes frustrating, woodworkers usually discover themselves in the position of requiring one or more new equipments nearly immediately.

The problem, obviously, is that revenue from enhanced manufacturing demand justifies the machinery purchase, however it can not be recognized without the equipment. In such covers, buying equipment used instead of financing new devices is the reasonable choice. When your income overtakes your production rate, you can get new equipment as you kindly.

4. You are beginning an official woodworking business

If you are going from being a casual woodworker to one who gains a source of income from his or her skills with timber, lessening business financing should be a main objective. The much less you owe, the a lot more earnings you could realize as income as well as placed toward developing your assembly line.

Acquiring made use of industrial equipment could need financing as well, however bear in mind, the less you financing, the much more you earn. For small businesses, this basic relationship could suggest the difference between success as well as failure. Buying professional woodworking equipment is a serious choice, however purchasing it pre-owned, like a used mori seiki, can make the decision easier.

Tuesday, February 17, 2015

Sinker EDM Machine: EDM Tooling Process

The modern-day mold making tool shop depends heavily on EDM machining, both with the sinker EDM machine and also wire EDM. It would be practically difficult to imagine contending in this extremely technological industry without making use of a thorough as well as integrated approach. This has also altered the nature of tasks connecting to this kind of machining procedure.

This approach is a lot different compared to the means things were done just a couple of years earlier. In this not-so-distant past, there were only manual machines as well as the operator utilized a mix of magic and science to achieve some pretty remarkable results. All you required, back then, was a vertical milling machine, a manual surface area mill and an engine lathe. The lathe was not really even that crucial, it need not be a precision one.

All this changed when the CNC EDM was created. Soon, every tool and also die shop had at least one of these new machines. Together with this came the development of accuracy tooling. The automated tool changer might be fulled of copper or graphite electrodes as well as the machine could run for days, untreated. There were early pioneers in EDM machining, as well as they established many ingenious electronic wiring innovations that made the procedure much more foreseeable as well as regulated. The wizardry aspect began to fade away. The Japanese ended up being significant contributors to this progressing procedure and also quickly many companies were pushing the process even further along.

All this changed when the CNC EDM was created. Soon, every tool and also die shop had at least one of these new machines. Together with this came the development of accuracy tooling. The automated tool changer might be fulled of copper or graphite electrodes as well as the machine could run for days, untreated. There were early pioneers in EDM machining, as well as they established many ingenious electronic wiring innovations that made the procedure much more foreseeable as well as regulated. The wizardry aspect began to fade away. The Japanese ended up being significant contributors to this progressing procedure and also quickly many companies were pushing the process even further along.

The high speed milling machine likewise totally transformed the means electrodes were produced. As an alternative of a mold maker spending hrs executing complex configurations on the surface area grinder, the electrodes are made in mins, much more precisely. These mills call for some really sophisticated carbide end mills as well as insert cutters to do their work. These ball end mills and bull nosed cutters can be coated with a huge variety of coatings.

The influence of slim production started to influence companies as well, as well as quickly there created work cells. The EDM machining procedure is now performed in a job cell that includes some really innovative machine tools.

The cell commonly includes the wire and also sinker EDM machine, a CMM, a broadband machining center, a hand-operated area mill and also an inspection location. This tooling is an absolutely amazing machine. It has completely changed the method injection molds as well as preciseness metal stamping dies are created and also produced.

This approach is a lot different compared to the means things were done just a couple of years earlier. In this not-so-distant past, there were only manual machines as well as the operator utilized a mix of magic and science to achieve some pretty remarkable results. All you required, back then, was a vertical milling machine, a manual surface area mill and an engine lathe. The lathe was not really even that crucial, it need not be a precision one.

All this changed when the CNC EDM was created. Soon, every tool and also die shop had at least one of these new machines. Together with this came the development of accuracy tooling. The automated tool changer might be fulled of copper or graphite electrodes as well as the machine could run for days, untreated. There were early pioneers in EDM machining, as well as they established many ingenious electronic wiring innovations that made the procedure much more foreseeable as well as regulated. The wizardry aspect began to fade away. The Japanese ended up being significant contributors to this progressing procedure and also quickly many companies were pushing the process even further along.

All this changed when the CNC EDM was created. Soon, every tool and also die shop had at least one of these new machines. Together with this came the development of accuracy tooling. The automated tool changer might be fulled of copper or graphite electrodes as well as the machine could run for days, untreated. There were early pioneers in EDM machining, as well as they established many ingenious electronic wiring innovations that made the procedure much more foreseeable as well as regulated. The wizardry aspect began to fade away. The Japanese ended up being significant contributors to this progressing procedure and also quickly many companies were pushing the process even further along.The high speed milling machine likewise totally transformed the means electrodes were produced. As an alternative of a mold maker spending hrs executing complex configurations on the surface area grinder, the electrodes are made in mins, much more precisely. These mills call for some really sophisticated carbide end mills as well as insert cutters to do their work. These ball end mills and bull nosed cutters can be coated with a huge variety of coatings.

The influence of slim production started to influence companies as well, as well as quickly there created work cells. The EDM machining procedure is now performed in a job cell that includes some really innovative machine tools.

The cell commonly includes the wire and also sinker EDM machine, a CMM, a broadband machining center, a hand-operated area mill and also an inspection location. This tooling is an absolutely amazing machine. It has completely changed the method injection molds as well as preciseness metal stamping dies are created and also produced.

Friday, January 30, 2015

The Role Of Used Mori Seiki in Manufacturing Companies

Used mori seiki takes an extremely important part in the manufacturing production nowadays. It is one of the world’s top producer of CNC machining centers, CNC lathes, and CNC turning centers. The business has formed the current device tool industry. If you check out the vocabulary, the unit is a thing made for a particular objective. It is a contrivance or creation, especially an electric or mechanized one. This pertains to an extensive of used tool such as different kinds of machines and instruments.

More Possibilities: To keep your budget balanced, there’s much money to spend to your warehouse/storage needs are probably not your ultimate priority. As you go through the succeeding path, you may swap minor equipment. When you choose used equipment, you will have the ability to save more money and be capable to purchase more.

Expected Lifespan: Not like the innovative equipment, the “life expectancy” of used equipment is expected. This permits you to estimate fairly the quantity of usage you will have the ability to get out of using the gear.

There are plenty of queries concerning the process of purchasing gear, but the easiest one is most likely the issue that ask with regards to: Should you purchase used or new equipment? While owning a new device may sound beneficial to you, always prioritize your convenience. To help you come up a sensible decision, the benefits have been presented. Bear in mind that is buying used mori seiki outweighs the drawbacks.

Mori Seiki Purposes

- Aerospace - throttle bodies, airline hydraulic cylinder, seat components, and secondary parts of operations.

- Green Energy/Power Generation - Gas fuel body, wind power tool.

- Defense/Military -firearm side handles, gun elements, and molds.

- Railway/Automotive-auto engine fuel pump body, a-arms, suspension parts, suspension, and brake components.

- Medical - molds, cavities, and cores.

- Agriculture- Farm equipment, hydraulic components, tractor hydraulic, farm equipment, and hubs.

Benefits Of Purchasing Used Equipment

It’s less costly: This is probably the greatest advantage of going with used mori seiki. In fact, it’s where the advantages came from. In many instances, going to used equipment won’t help you save much. But other times, the cost variation make it difficult to say no. Almost everything has a price. Nowadays, most things have a higher value. With the high cost of living, purchasing “used” equipment has become progressively popular. Purchasing used equipment can save plenty of cash.More Possibilities: To keep your budget balanced, there’s much money to spend to your warehouse/storage needs are probably not your ultimate priority. As you go through the succeeding path, you may swap minor equipment. When you choose used equipment, you will have the ability to save more money and be capable to purchase more.

Expected Lifespan: Not like the innovative equipment, the “life expectancy” of used equipment is expected. This permits you to estimate fairly the quantity of usage you will have the ability to get out of using the gear.

There are plenty of queries concerning the process of purchasing gear, but the easiest one is most likely the issue that ask with regards to: Should you purchase used or new equipment? While owning a new device may sound beneficial to you, always prioritize your convenience. To help you come up a sensible decision, the benefits have been presented. Bear in mind that is buying used mori seiki outweighs the drawbacks.

Tuesday, January 20, 2015

Used Vertical Turning Lathe: Lathes as Useful Tools for Most Industries

A device which revolves a workpiece on an axis in order to allow for a variety of completely in proportion operations which can include sanding, reducing, drilling or other sort of contortion is known as a lathe. Simply puts the worker will certainly position a things or product into the tool, maybe a brand new or used vertical turning lathe, as well as it will certainly then reverse 360 degrees continuously. By merely holding the carry out in the proper place then, a hobbyist or professional is able to make modification that will certainly affect the whole circumference of the material.

Lathes are utilized in a variety of different industries as well as there are an array of prominent tools related to their usage. The potter's wheel for instance which is extremely preferred is a kind of lathe. It is likewise feasible to ornamental lathes that are designed to be decorative and also collectible. There are also several different types lathe and parts of lathes. Typically the lathe will consist of a pin on which the item will transform, a tool remainder for standing the tool, a tail stock and a lock nob.

The lock nob is used in order to alter and afterwards set the elevation of the tool remainder in order to make sure that the tool that is made use of in order to form the object is held stable and also at the same elevation. Or else you would be likely to find that you ended up drawing strange shaky lines on the things instead of keeping them still therefore developing a straight line. As the object rotates the tool will alter the shape, but because it won't move it won't go into the things despite how many times it is rotated. Hence the line will be totally even all around and also you could then change the position of the tool before making new modifications.

Other portals which lathes vary are that some will turn the object horizontally while others will certainly turn it vertically. On the other hand you will certainly find that some lathes are electrical while older lathes call for a pedal or a deal with in order to cause the challenge revolve. Naturally the rate at which the product revolves is very important too as this effect how well the item cuts depending on the material you are making use of. Lathes additionally vary a lot in size, and also while some are small adequate to be raised and put on a bench or a table, others will certainly be huge as well as will certainly stand openly on workshop floors etc.

The tools that you make use of to apply to the item on the lathe, or a new or utilized vertical turning lather, can additionally vary extensively and these can consist of paintbrushes for painting points that have already set, blades for reducing lines, sanders and declare submitting things down, flamethrowers for collaborating with glass etc and more. In many cases, such as the potters wheel, just hands will certainly be enough to change the form of the clay.

Lathes are utilized in a variety of different industries as well as there are an array of prominent tools related to their usage. The potter's wheel for instance which is extremely preferred is a kind of lathe. It is likewise feasible to ornamental lathes that are designed to be decorative and also collectible. There are also several different types lathe and parts of lathes. Typically the lathe will consist of a pin on which the item will transform, a tool remainder for standing the tool, a tail stock and a lock nob.

The lock nob is used in order to alter and afterwards set the elevation of the tool remainder in order to make sure that the tool that is made use of in order to form the object is held stable and also at the same elevation. Or else you would be likely to find that you ended up drawing strange shaky lines on the things instead of keeping them still therefore developing a straight line. As the object rotates the tool will alter the shape, but because it won't move it won't go into the things despite how many times it is rotated. Hence the line will be totally even all around and also you could then change the position of the tool before making new modifications.

Other portals which lathes vary are that some will turn the object horizontally while others will certainly turn it vertically. On the other hand you will certainly find that some lathes are electrical while older lathes call for a pedal or a deal with in order to cause the challenge revolve. Naturally the rate at which the product revolves is very important too as this effect how well the item cuts depending on the material you are making use of. Lathes additionally vary a lot in size, and also while some are small adequate to be raised and put on a bench or a table, others will certainly be huge as well as will certainly stand openly on workshop floors etc.

The tools that you make use of to apply to the item on the lathe, or a new or utilized vertical turning lather, can additionally vary extensively and these can consist of paintbrushes for painting points that have already set, blades for reducing lines, sanders and declare submitting things down, flamethrowers for collaborating with glass etc and more. In many cases, such as the potters wheel, just hands will certainly be enough to change the form of the clay.

Monday, December 29, 2014

Used Small Hole EDM: Things That This Device Can Do

The expression EDM or an abbreviation of Electrical Discharge Machining is a machine that uses electric discharges to shape or establish a metal which is difficult to do utilizing typical methods. It uses electric discharges on items of steel that are electrically conductive to be able to produce different kinds of elaborate shapes with metals. Normally, forms that are difficult to produce with a mill, a reducing tool or an end mill are developed utilizing any kind of this tool, may it be new or currently used small hole EDM tool.

This kind of machine undoubtedly has a not-so-cheap price; but it has several uses. Some of which are as follows:

1. Exceptionally tough steels may be quickly reduced.

Difficult steels are not merely difficult, however are likewise really pricey compared to their soft counterparts. With an EDM you will certainly never ever have to manage product wastage and problems with precision cuts given that you are utilizing reliable and also accurate cutting as well as shaping instruments.

2. EDM devices like wire EDM machines are excellent in producing complex forms which are difficult to use conventional cutting tools.

You will be able to make accurate steel parts in the most efficient as well as sensible method as compared to shaping or reducing steels, which could possibly take for life to do.

3. With the EDM technique, there is no call from the machine to the material or piece of metal that is being treated.

With this tool, there is no distortion or errors that may happen from a tool making contact with the product or steel. These high qualities are essential particularly when the industry needs severe preciseness like making elements for digital gadgets.

4. If you are developing elements that have very small and accurate openings then, you will absolutely require an EDM machine because it is difficult to drill minute holes on steels and extremely hard steels with typical tools and techniques.

5. Compared with reducing or shaping and also developing parts using common approaches, EDM machines will certainly produce a smooth finish on the metal.

This is optimal for preciseness and excellent quality machine, tool and tools parts.

6. From the largest tool components, EDM tools will be able to develop the smallest elements of machines, engines and also digital parts.

Fragile steel as well as steel parts are normally really difficult to make and also might be delicate or weak when typical tools are used. EDM's will produce these parts with severe accuracy and with no sort of distortion that could possibly impact the feature of a certain part or part.

There are specialized used small hole EDM machines that will work for the industry or business that you are in. Make sure to check out on-line sources and on the internet machine and also devices sales sites for the ideal electrical discharge machine that will certainly work for your business.

This kind of machine undoubtedly has a not-so-cheap price; but it has several uses. Some of which are as follows:

1. Exceptionally tough steels may be quickly reduced.

Difficult steels are not merely difficult, however are likewise really pricey compared to their soft counterparts. With an EDM you will certainly never ever have to manage product wastage and problems with precision cuts given that you are utilizing reliable and also accurate cutting as well as shaping instruments.

2. EDM devices like wire EDM machines are excellent in producing complex forms which are difficult to use conventional cutting tools.

You will be able to make accurate steel parts in the most efficient as well as sensible method as compared to shaping or reducing steels, which could possibly take for life to do.

3. With the EDM technique, there is no call from the machine to the material or piece of metal that is being treated.

With this tool, there is no distortion or errors that may happen from a tool making contact with the product or steel. These high qualities are essential particularly when the industry needs severe preciseness like making elements for digital gadgets.

4. If you are developing elements that have very small and accurate openings then, you will absolutely require an EDM machine because it is difficult to drill minute holes on steels and extremely hard steels with typical tools and techniques.

5. Compared with reducing or shaping and also developing parts using common approaches, EDM machines will certainly produce a smooth finish on the metal.

This is optimal for preciseness and excellent quality machine, tool and tools parts.

6. From the largest tool components, EDM tools will be able to develop the smallest elements of machines, engines and also digital parts.

Fragile steel as well as steel parts are normally really difficult to make and also might be delicate or weak when typical tools are used. EDM's will produce these parts with severe accuracy and with no sort of distortion that could possibly impact the feature of a certain part or part.

There are specialized used small hole EDM machines that will work for the industry or business that you are in. Make sure to check out on-line sources and on the internet machine and also devices sales sites for the ideal electrical discharge machine that will certainly work for your business.

Tuesday, November 11, 2014

Brand-new or Used Wire EDM Machines and the Processes Involved

Wire Electric Discharge Machining is a machining procedure that uses a cable filament that lugs an electric cost via the cable and also is utilized to remove the tough steel components. When doing this, it would certainly not matter whether business would certainly utilize new or used wire EDM machines. What is more crucial is the durability of the equipment.

There are 2 significant elements needed for the wire EDM tool, not the least which is the cord made use of to take out the metal in order to form the item being produced. The level of accuracy as well as the quantities of products that can be gotten rid of with succeeding passes are significantly figured out by the make-up of the cord, commonly copper cable, in addition to the kind and also toughness of the electric existing. The higher the dimensions of the cord, the even more product that could be reduced with each pass; nonetheless, the give-and-take with the bigger dimension cord is that the level of accuracy is lessened.

Many wire EDM tools today are CNC-controlled tools. As opposed to rely upon the rather incorrect as well as inaccurate eyeball method, contemporary wire EDM machines depend exclusively after computer systems to guide the cables to remove just the steel that should be taken out. In order to reduce designs with better preciseness and also in order to produce 3D items, these machines have cables that inhabit not simply the conventional X and also Y axis yet additionally the U and also V axis for a typical 4-axis tooling however could likewise have a Fifth gain access to for also higher preciseness.

The 2nd element of wire EDM is that the steel being functioned is typically put as well as tooled in a tub of liquid, usually a Deionized water which regulates the conductivity of the cord for a far better cut along with to assist keep the core temperature levels down. As is frequently recognized, electric currents travelling through steels boost interior temperature levels and also steel tooled in greater warmth settings becomes much less firm as well as have a decline of tensile toughness. An added benefit of tooling in water is to assist take out chips as well as bits from the workspace lessening the quantity of unintentional rating of the end product along with to minimize the general "warmth afflicted area.".

One last benefit to machining in liquid is that it assists to prolong the life of the cord itself. Brand-new or perhaps used wire EDM machines are higher upkeep. The cables must be looked for matching, racking up, breaks, and also various other failures regularly. Documentation of any of these if left neglected, could create incorrect tooling of the things, loss of precision and even damages to the machine. By simply tooling in liquid, the cords are kept colder and also the electric fees gone through the cables are preserved at a constant rate, therefore prolonging the cable lives.

There are 2 significant elements needed for the wire EDM tool, not the least which is the cord made use of to take out the metal in order to form the item being produced. The level of accuracy as well as the quantities of products that can be gotten rid of with succeeding passes are significantly figured out by the make-up of the cord, commonly copper cable, in addition to the kind and also toughness of the electric existing. The higher the dimensions of the cord, the even more product that could be reduced with each pass; nonetheless, the give-and-take with the bigger dimension cord is that the level of accuracy is lessened.

Many wire EDM tools today are CNC-controlled tools. As opposed to rely upon the rather incorrect as well as inaccurate eyeball method, contemporary wire EDM machines depend exclusively after computer systems to guide the cables to remove just the steel that should be taken out. In order to reduce designs with better preciseness and also in order to produce 3D items, these machines have cables that inhabit not simply the conventional X and also Y axis yet additionally the U and also V axis for a typical 4-axis tooling however could likewise have a Fifth gain access to for also higher preciseness.

The 2nd element of wire EDM is that the steel being functioned is typically put as well as tooled in a tub of liquid, usually a Deionized water which regulates the conductivity of the cord for a far better cut along with to assist keep the core temperature levels down. As is frequently recognized, electric currents travelling through steels boost interior temperature levels and also steel tooled in greater warmth settings becomes much less firm as well as have a decline of tensile toughness. An added benefit of tooling in water is to assist take out chips as well as bits from the workspace lessening the quantity of unintentional rating of the end product along with to minimize the general "warmth afflicted area.".

One last benefit to machining in liquid is that it assists to prolong the life of the cord itself. Brand-new or perhaps used wire EDM machines are higher upkeep. The cables must be looked for matching, racking up, breaks, and also various other failures regularly. Documentation of any of these if left neglected, could create incorrect tooling of the things, loss of precision and even damages to the machine. By simply tooling in liquid, the cords are kept colder and also the electric fees gone through the cables are preserved at a constant rate, therefore prolonging the cable lives.

Subscribe to:

Comments (Atom)