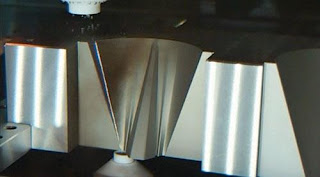

Used wire EDM machines have played an important part in the advancement of the manufacturing department. Primarily, it is a process of metalworking with the aid of which material sets apart from a conductive work piece through electrical erosion. As a result, the wire indeed not very conducive material. The wire electrode will leave a path on the piece, which appears to be larger than the wire.

Implementations Of Used EDM Machines

Used wire EDM machines are primarily used to cut hard patterns and shapes into hard metals, which are hard to mold, manipulate or form. It is advantageous in the aerospace and electronic devices sectors for production and prototyping various parts. In most cases, titanium and steel are highly processed with the assistance wire electrical discharge machining. To trim complex designs like jewelry, this device is used. Also, artists dealing with metals think that machining gear is useful and handy to use. For the most of applications, they are utilized to generate precision parts. Some markets such as medical related, automobile, aerospace, protection, and semiconductor/electric manufacturing will need wire EDM to accomplish firmer tolerances and high precision.

The majority of wire EDM equipment is CNC-controlled. The CNC phrase means "Computer Numerical Control." The objective is to achieve an accurate and precise strategy via a machine, rather than counting on imprecise and incorrect "eyeball" approach. This contemporary wire machine depends solely upon computer systems to guide and chop the wires away. But only the metal is taken out. To cut designs with accuracy and to produce 3D objects, the used EDM machines have proven to be advantageous.

One last benefit of fluid machining through this used machine to lengthen the lifespan of the wire itself. These systems are high maintenance simply because the wires are checked for rating, pitting, damages, and other downfalls frequently. If left abandoned, proof of any of these could lead to the indecent tooling of the item, damage to the device or lack of precision. Through fluid tooling, the wires are retained cool, and the constant rate is utilized in the electrical charges that passed through the wires, thus stretching the life expectancy of the wire.

Each and every machine procedure and electrical discharge machining call for the best EDM supplies. Machining of this kind is used to generate finely detailed parts. They are progressively becoming prominent in the manufacturing sector throughout the world. They are utilized mainly by the production companies in dying of supplies. There are plenty of companies promoting these stuffs, but be sure you obtain the best-used wire EDM machines.